Buyers notice:

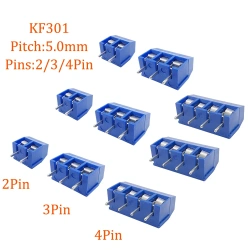

*Please allow 1-3mm error due to manual measurement. pls make sure you do not mind before you bid

*Due to the difference between different monitors, the picture may not reflect the actual color of the item.

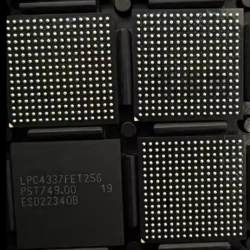

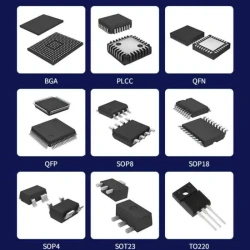

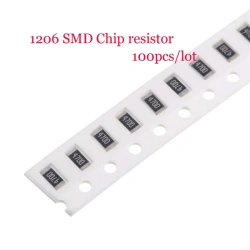

*Our company can buy other Electronic accessory and IC parts for you. You should tell us clearly about the product's grade, suffix,encapsulation, Brands and so on.

*Our company is an entity administration. We have lots of grades that we can't upload all of them.Lot quality buying will be much cheaper.

*Avoid the damage or loss in transmission. Please seriously check the parts when you receive them. Do not sign in if there's something wrong. And contact me at once. Let's solve the problem together.

Disclaimer - Information Sharing

Our website/platform (hereinafter referred to as "the site") is intended to provide various types of information, including but not limited to news, articles, opinions, comments, data, and other resources, for the reference and understanding of our users. While using the site, please be aware of the following disclaimer:

- Accuracy of Information: We make every effort to ensure that the information provided is accurate, comprehensive, and up-to-date. However, we cannot guarantee the 100% accuracy of the information. Therefore, we are not responsible for any losses or damages incurred due to reliance on the information on this site.

- Purpose of Information: The information provided on this site is for general reference and information sharing purposes and does not constitute professional advice. Any decisions or actions should be based on independent professional consultation and judgment. Exercise caution before taking any action.

- Third-Party Links: The site may contain links to third-party websites or resources. These links are provided for convenience, and we are not responsible for the content or accuracy of these links. Accessing these links is at your own risk.

- Intellectual Property: All content on this site, including but not limited to articles, images, videos, and other resources, is protected by intellectual property laws. Unauthorized copying, reproduction, or use of this content in any way is prohibited.

- Changes and Updates: Information on this site and the disclaimer may change or be updated at any time without prior notice. You should check regularly for the latest information.

- User Responsibility: Your use of all information and resources on this site is at your own discretion and risk. We are not responsible for any losses or damages you may incur when using the information on this site.

By using this site, you agree to and accept these disclaimers. If you do not agree with these terms, please discontinue using the site. If you have any questions about using the site or need further clarification, please feel free to contact us. We welcome and encourage users to share information but also strongly advise exercising caution and self-judgment in any decision-making.